From concept to clearance…

We lead, support, or supplement your product development effort at all stages of the product lifecycle— we integrate seamlessly with your team to help make your products come to life.

Turn requirements

into results.

Ontogen provides standards-based testing services that translate regulatory and quality requirements into clear, actionable evidence. From development screening through validation and ongoing monitoring, we deliver well-documented methods, straightforward reporting, and practical engineering insight—so you can make confident decisions and move programs forward.

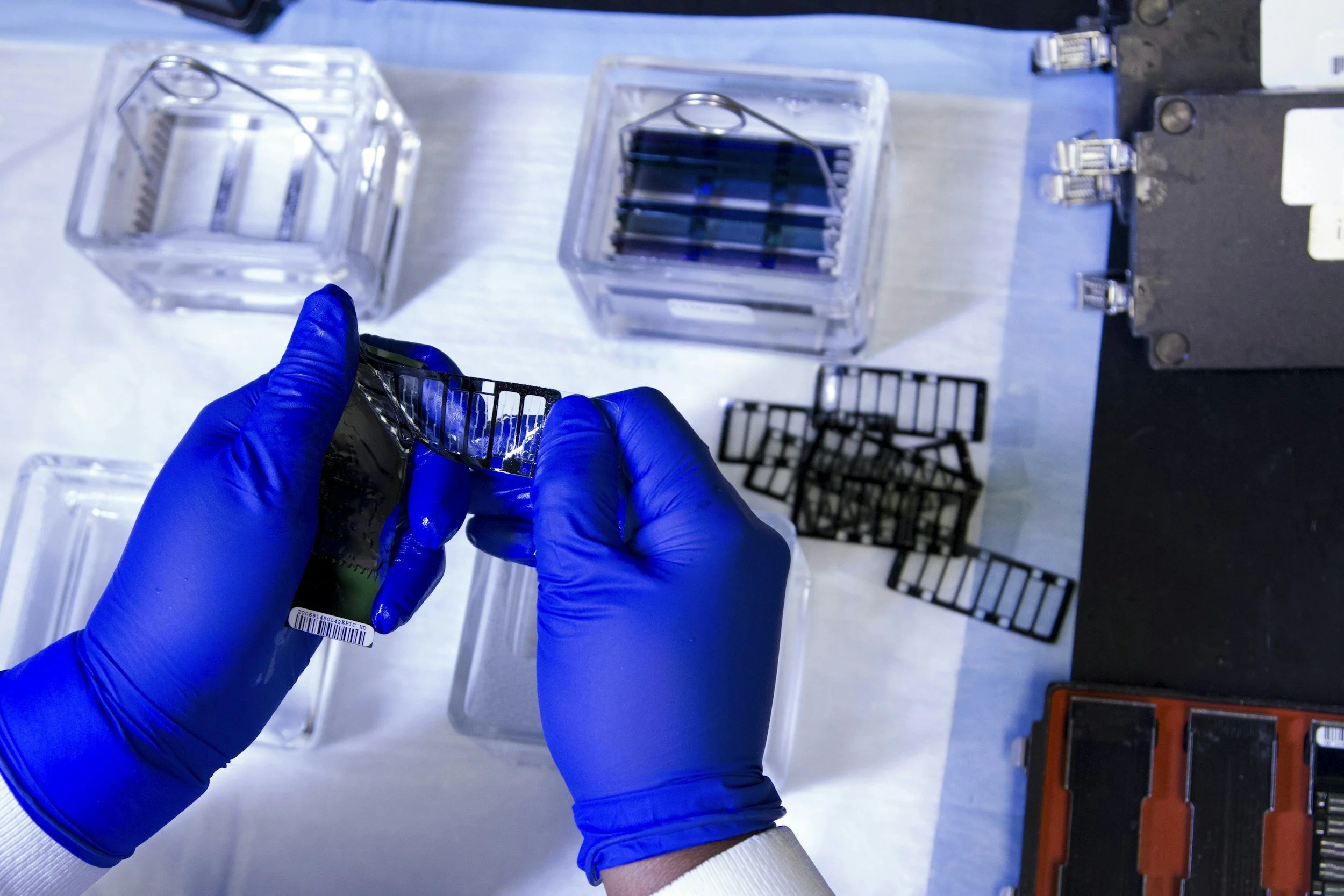

Bubble Leak Testing

ASTM F2096

Ontogen offers bubble leak testing per ASTM F2096 to help verify the gross leak integrity of sterile barrier packaging—especially pouches and tray systems—as part of package development, validation, and ongoing quality control. Using controlled internal pressurization under water, this method enables rapid detection and location of leak paths (e.g., pinholes, channels, seal defects) indicated by a continuous stream of bubbles.

Common uses

Packaging development screening and troubleshooting (seal/process changes, material changes)

ISO 11607 packaging validation support and routine monitoring

Incoming inspection / supplier checks / lot release screening for gross leaks

Peel Seal Testing

ASTM F88

Ontogen offers peel seal testing for Tyvek® sterile barrier packaging per ASTM F88 to help verify seal strength and peel performance of pouches and lidstock-tray systems—supporting package development, validation, and ongoing quality control. Using controlled mechanical peel testing, we measure seal strength and evaluate peel behavior (e.g., consistent fiber tear vs. clean peel, channels, weak seals, or over-sealing) to help confirm your packaging opens as intended while maintaining sterile barrier integrity.

Common uses

Packaging development screening and troubleshooting (seal parameters, dwell/temperature/pressure changes, material changes)

ISO 11607 packaging validation support and routine monitoring

Incoming inspection, supplier verification, and lot-release checks for seal strength and peel consistency

Accelerated Aging

ASTM F1980

Ontogen offers Accelerated Aging studies per ASTM F1980/F1980M to support shelf-life claims for sterile barrier packaging systems (e.g., Tyvek® pouches, tray-and-lid systems) as part of package development, validation, and ongoing quality planning. Using controlled elevated-temperature conditioning based on Arrhenius principles, accelerated aging helps simulate the effects of time so you can evaluate packaging integrity and seal performance at the intended shelf life—without waiting years for real-time aging.

Common uses

Shelf-life validation planning to support ISO 11607 packaging validation activities

Comparing packaging materials or seal process changes for impact on long-term performance

Bridging or supplemental data alongside real-time aging to de-risk timelines

FREQUENTLY ASKED QUESTIONS

-

Yes. When published standards don’t match your geometry, materials, or use conditions, we can design a fit-for-purpose method that targets your actual risk points. We document the rationale, fixtures, parameters, and acceptance criteria so the method is repeatable and reviewable. When needed, we also validate the method itself—establishing key performance characteristics (e.g., repeatability/reproducibility, sensitivity, and operator/fixture effects) and defining controls—so the results are defensible for validation, audits, and decision-making.

-

Yes—deliverables typically include a clear summary of the method, test conditions, results, observations (including failure modes), and any deviations. We can align the reporting format to your internal templates when needed. If you’re using the data for a validation package, we’ll structure it for easy incorporation.

-

Yes—failure analysis and troubleshooting are common use cases. We can help replicate conditions, localize failure modes (e.g., channel leaks, weak seals, over-sealing), and provide practical recommendations for next experiments. The focus is on actionable root-cause direction, not just a pass/fail.